Cut-to-Length Line

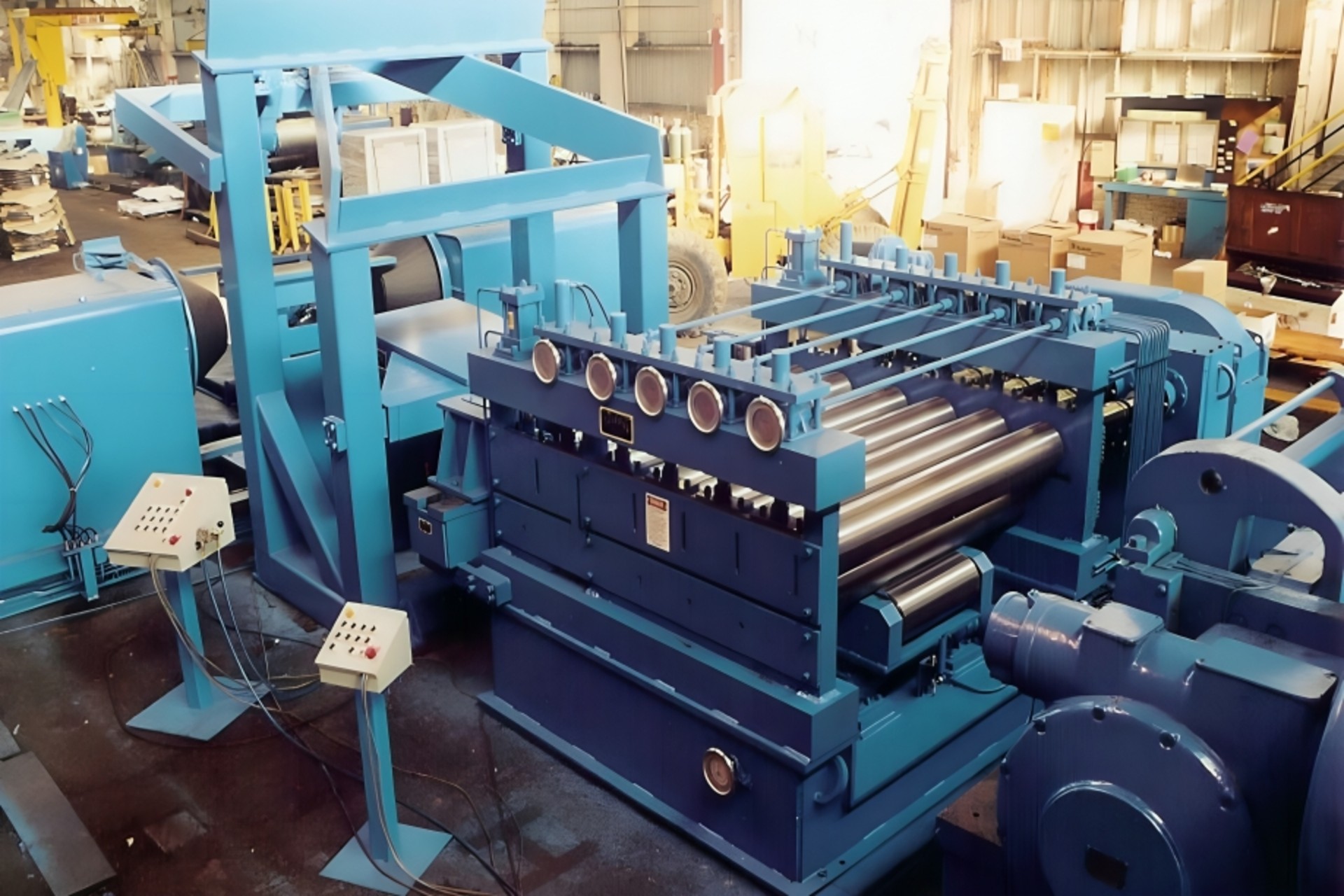

At Sajjanson Engineers, we specialize in designing and delivering state-of-the-art Cut-to-Length (CTL) Lines that cater to diverse industrial needs. Our CTL lines uncoil, straighten, cut, and stack materials with precision, ensuring top-quality sheets for various applications.

What is a Cut-to-Length Line?

A Cut-to-Length (CTL) Line processes rolled material into flat sheets by performing the following steps:

Unrolling and Flattening: Straightens the material for a smooth finish.

Precision Cutting: Cuts sheets to precise lengths.

Edge Trimming & Scrap Cutting: Ensures neat and clean edges.

Sheet Stacking: Stacks the cut sheets into bundles for further use.

Our lines are designed to handle a wide range of materials such as hot-rolled, cold-rolled, galvanized, pre-painted, stainless steel, aluminum, copper, and brass coils.

CTL Production Process

The CTL process includes:

Coil Loading: Loading and unwinding of the metal coils.

Flattening: Straightening of material for superior flatness.

Cutting: High-precision shearing for accurate lengths.

Stacking: Automated stacking of sheets into bundles.

Our CTL lines are equipped with inline systems such as uncoilers, levelers, roll feed machines, shears, and stackers to ensure precision, efficiency, and productivity.

Key Features of Sajjanson CTL Lines

Category |

Specifications |

|---|---|

| Material Thickness Range | 0.2 mm - 28 mm |

| Strip Width | Up to 2,200 mm |

| Coil Weight | Up to 40 Tons |

| Line Speed | Up to 85 m/min |

| Yield Strength | Up to 900 MPa |

Types of CTL Lines

We offer CTL lines designed for varying industrial needs:

1. LIGHT CTL Lines

Material Thickness: 0.2 to 3 mm

Coil Weight: Up to 30 Tons

Line Speed: Up to 85 m/min

Applications: Ideal for light-gauge sheets and flexible operations.

2. MEDIUM CTL Lines

Material Thickness: Up to 8 mm

Coil Weight: Up to 30 Tons

Line Speed: Up to 60 m/min

Applications: Suitable for mid-gauge sheets and high production rates.

3. HEAVY CTL Lines

Material Thickness: Up to 16 mm

Coil Weight: Up to 40 Tons

Line Speed: Up to 30 m/min

Applications: Engineered for heavy-gauge sheets and high-strength materials.

Special Features of Our CTL Lines

Rotary Shear Technology: Ensures high-speed precision cutting.

Dual Leveler System: Achieves superior flatness for critical applications.

Automation: Streamlines operations for enhanced productivity.

Versatility: Handles a wide range of materials, including ferrous and non-ferrous metals.

Customization: Tailored solutions to meet specific production requirements.

Applications of CTL Lines

Automotive Industry

Electrical and Transformer Components

Construction Materials

Pipe and Tube Manufacturing

Pre-Painted & Coated Steel Sheets

Why Choose Sajjanson Engineers?

With years of expertise and cutting-edge technology, Sajjanson Engineers provides Cut-to-Length Lines that combine precision, efficiency, and durability. Our lines are designed to offer the best-in-class solutions for your production needs.

Contact Us

For inquiries or to learn more about our Cut-to-Length Lines, reach out to Sajjanson Engineers today! Let us help you optimize your production process with the most efficient and reliable CTL solutions.